Features

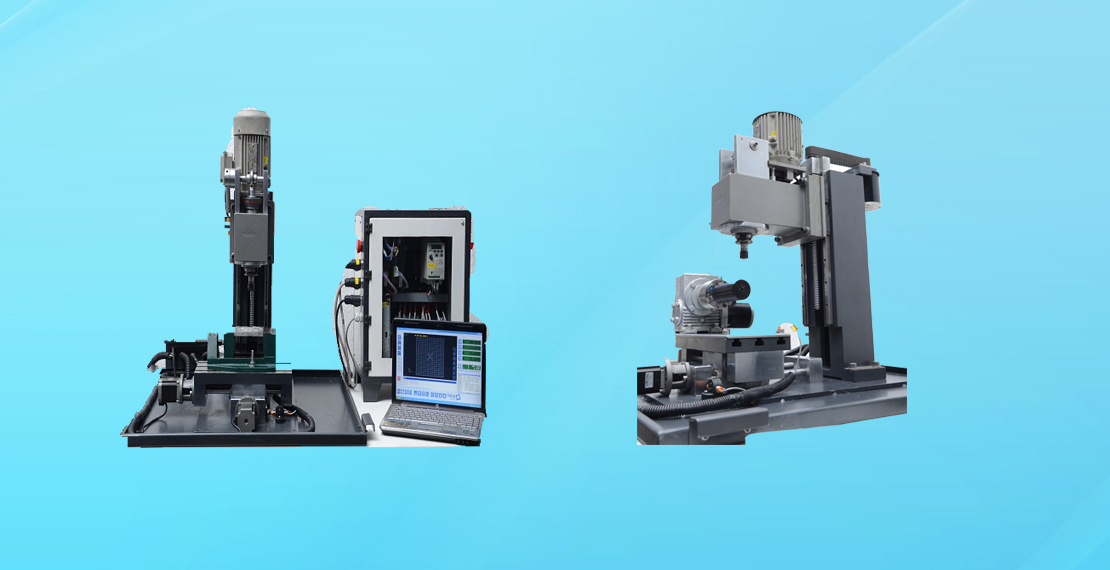

- Indigenously developed and manufactured CNC Training Machines

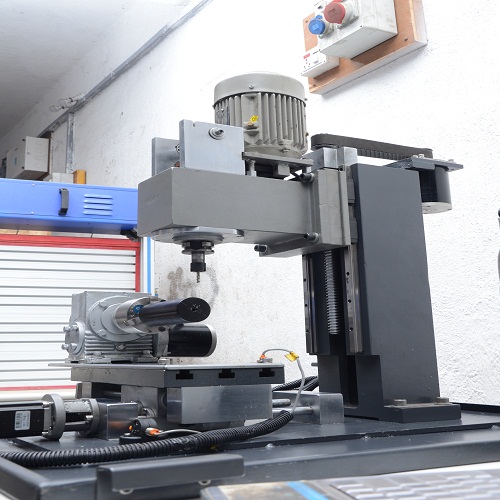

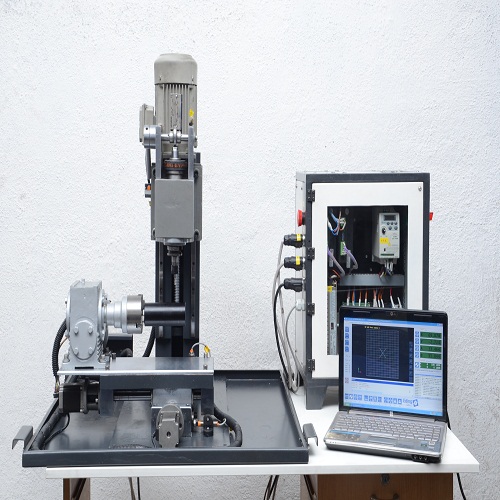

- 4 Axes Simultaneous Interpolation

- Removable 4th Axis Assembly

- Linear Motion Guide ways

- Can machine Aluminum

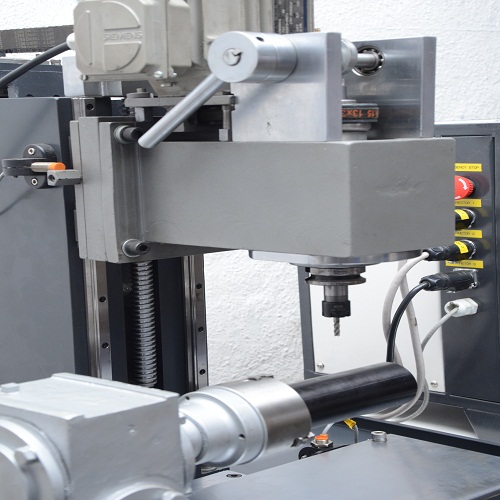

- Manual Pulse Generator (MPG)

- AC Motor for Spindle with VFD for speed control

- Manual quick change tool post

- Option of Carbide / HSS Cutting Tools

- BT30 Tool Holder with Collet Chuck

- Automatic CNC code generation from DXF file

- MDI, JOG, AUTO mode

- Emulation of Siemens 828D Controller

- Single Step / Program Test / ROV

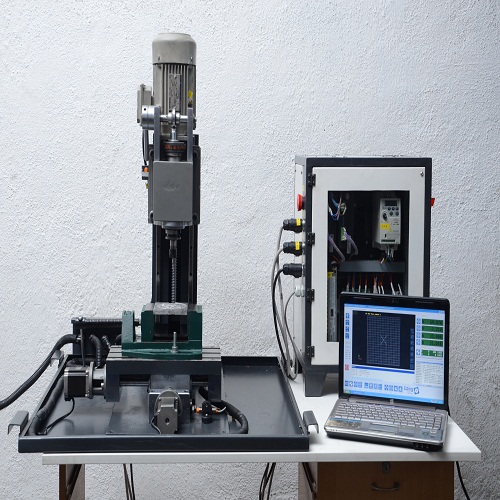

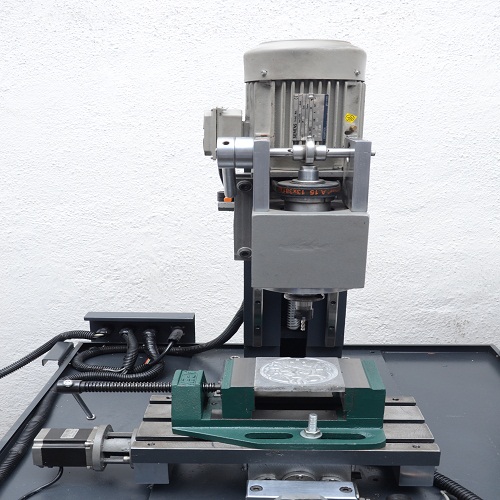

CNC Mill Trainer

Model | Giant 130 |

| Controller | PC Based, Emulation of Siemens 828D |

| No of Axes | 4 |

| Feed Motors | Stepper Motor with Stepper Drive, 4A |

| Head Spindle Motor | 0.75 HP, AC Induction Motor |

| Head Spindle Speed Variation | Through VFD |

| Max Positioning Speed | 500 mm/min |

| Head Spindle | ISO 30, 3000 RPM ER16 Collet |

| Vice | Manual Chuck - 75mm x 75mm |

| Accuracy | 0.02mm |

| Machining On | Aluminum |

| X Axis | 130 mm (Expandable) |

| Y Axis | Y Axis |

| Z Axis | 150 mm (Expandable) |

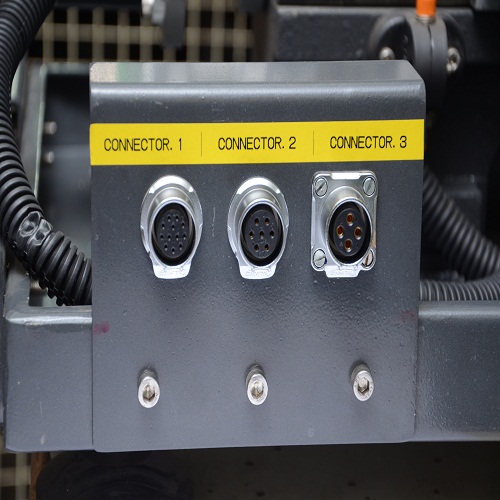

- Easy to connect

- Perpetual license for CAM software

- TCP/IP Communication

- Industrial Connectors (IP 68)

- Optional MOP

- Easy Portable

- Simulation mode / Machining Mode

- Separate Electrical Panel